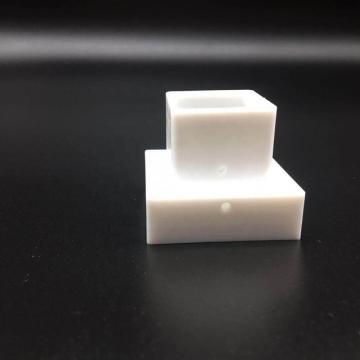

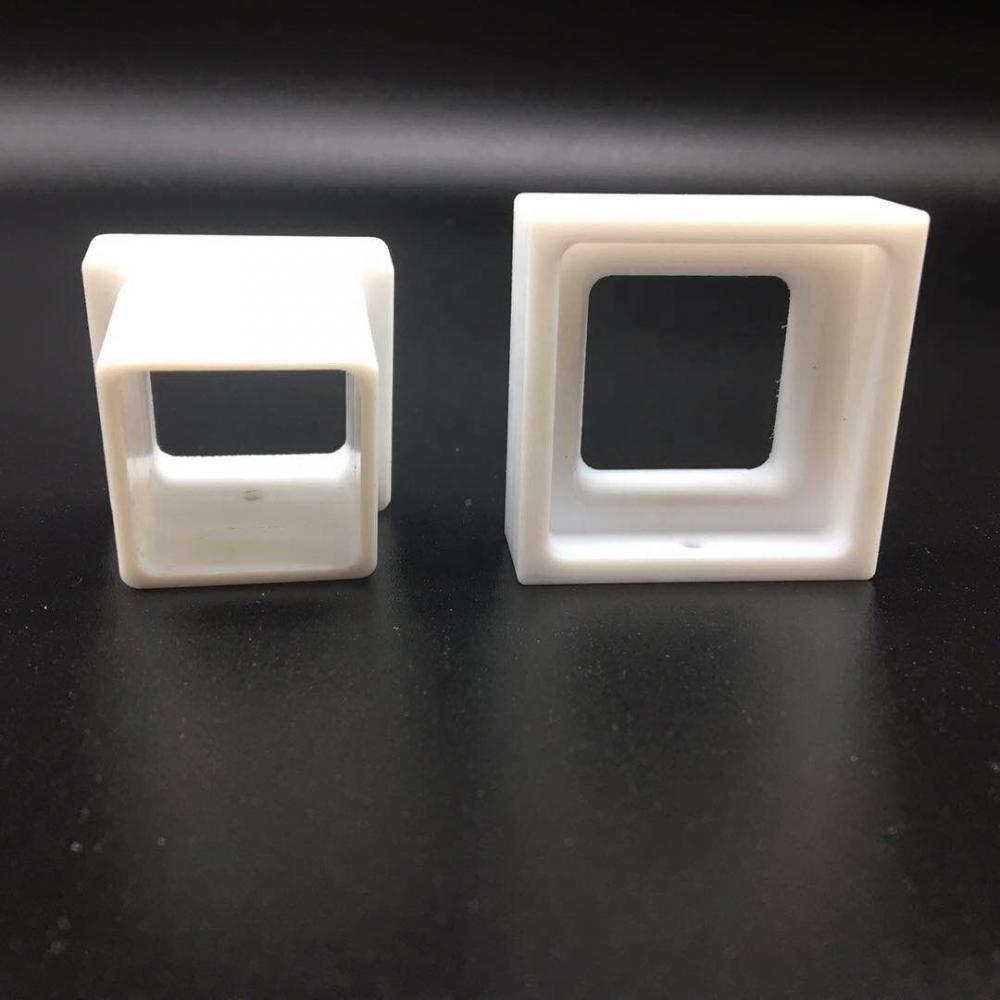

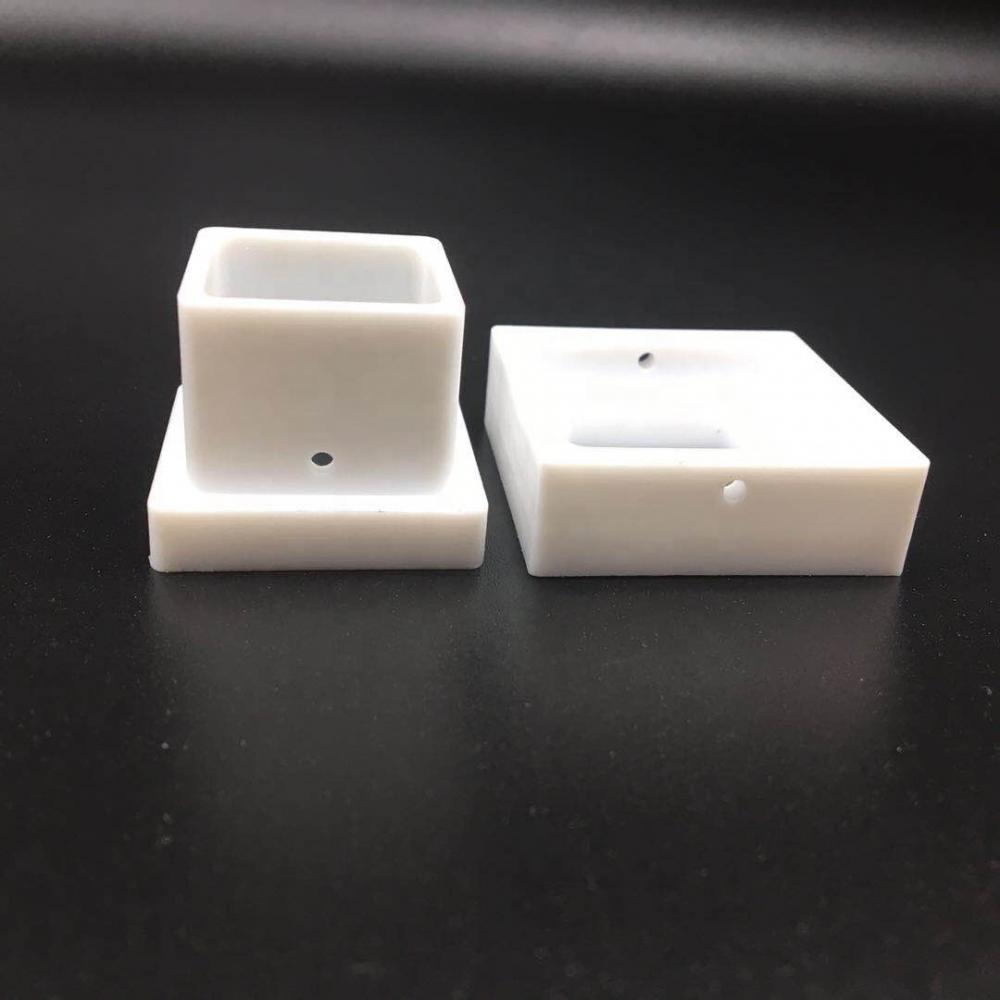

Precision Machining Parts peek

Product Description

Main application areas of PEEK

The automotive (including aviation) transportation market accounted for about 50% of PEEK resin consumption, semiconductor manufacturing Equipment accounted for 20%, general machinery parts products such as compressor valves accounted for 20%, and other markets such as medical equipment and analytical Instruments accounted for 10%.

1. Transportation machinery, such as automobiles

The growth of PEEK resin in The European market is especially rapid in the automotive parts market, especially in the parts around the engine, transmission parts, steering parts and so on, PEEK plastic is used instead of some traditional high-priced metals as manufacturing materials. Demand for PEEK resin will continue to grow as the automotive industry ADAPTS to miniaturization, lightweight, and cost reduction requirements. One European model uses PEEK plastic instead of metal for 44 parts.

2. IT manufacturing industry

Semiconductor manufacturing and the electronic appliance industry are expected to be another growth point for PEEK resin application. In the semiconductor industry, in order to achieve high function and low cost, the size of silicon chip is required to be larger, and the manufacturing technology is more advanced. Low dust, low gas release, low ion dissolution and low water absorption are the special requirements for various equipment materials in the semiconductor manufacturing process, which will be the place where PEEK resin will show its talent.

3, office machinery parts field

For separation claws, special heat-resistant bearings, chains, gears, etc. of photocopiers, PEEK resin can be used instead of metal as their material to make parts lightweight, fatigue resistant, and oil-free lubrication.

4. Wire covering field

PEEK coating has excellent flame retardant, without any flame retardant, its flame retardant class can reach UL94 V-0. PEEK resin also has peel resistance, irradiation resistance (109 rad) and other advantages, so it is used in special Wires and nuclear related fields.

5, plate, bar and other fields

In the application process of PEEK in some special fields, it often meets the phenomenon of less quantity and more varieties, so it is very advantageous to use bars, plates and other profiles for mechanical processing and manufacturing.

6. Fiber field

PEEK fiber (including monofilament) industrial press cloth, industrial brush products. In the field of composite materials, PEEK fiber's appeal lies in its thermoplastic and high temperature resistance. In addition to the heat resistance of industrial press cloth and industrial brush, its charm also lies in its chemical resistance and wear resistance.

7. Medical analytical devices

Because PEEK is resistant to repeated autoclaving, it can be used in medical devices to manufacture endoscope parts, dental descaling devices, etc. In addition, PEEK has been used in instrumental analysis of liquid chromatography columns, tubes, accessories, etc., due to its high strength and low solubility. PEEK has successfully replaced titanium as an artificial bone material because of its good compatibility with the human body.

FAQ

Q1:Will we Wo sign Non-Disclosure Agreements(NDA) ?

A:Yes.If it gives you peace-of-mind to sign an NDA,we are more than w ling to do so.But we have the rightkeep your design in confidential no matter NDA is signed or not.All factories are camera monitored.

Q2:How do I get a quote?

A:Please kindly provide us 3D or CAD solid model in Step, IGS,X_T format, normally Two-dimensional(2D)drawings are not adequate for accurate quoting or parts making B.Please tell us your requirement on quantisurface treatment.Color material,application enviranment for accurate pricing.

Q3:How quickly can l get my parts?

A:Quality parts can be made in 3-5 days if you provide us with complete 2Dand3DCAD models.Morecomplex parts requiring or other special features will take longer.As for shipping,most of our shipments arevia DHL, UPS,Fedex,which can take a few days from China to Europe or NorthAmerica.

Q4;How you do the quality control?

A: a.Materials inspection by IQC.

b.The fist sample inspected by QC,QC wild o over check as per the parameters list and critical dimensic requested by customers, to decide if it can go ahead for production.

c.During processing# our IP QC will check the injection molded parts every 2 hours,ensure no any rejects.

d.FQC will check the products before sending to the warehouse.

e.100% inspected by O QC before shipping out.

Contact us if you need more details on OEM Precision Machining Parts. We are ready to answer your questions on packaging, logistics, certification or any other aspects about OEM Metal Machining Parts、OEM Precision Machining Parts Peek. If these products fail to match your need, please contact us and we would like to provide relevant information.